Understanding Thermal Management Materials in Electronics

Thermal management materials are essential components in the design and functionality of electronic devices. They help to dissipate heat more effectively, ensuring that devices perform at optimal levels and have longer lifespans. The growing demand for electronic devices, coupled with their increasing complexity, makes the need for advanced thermal management materials more crucial than ever.

What are Thermal Management Materials?

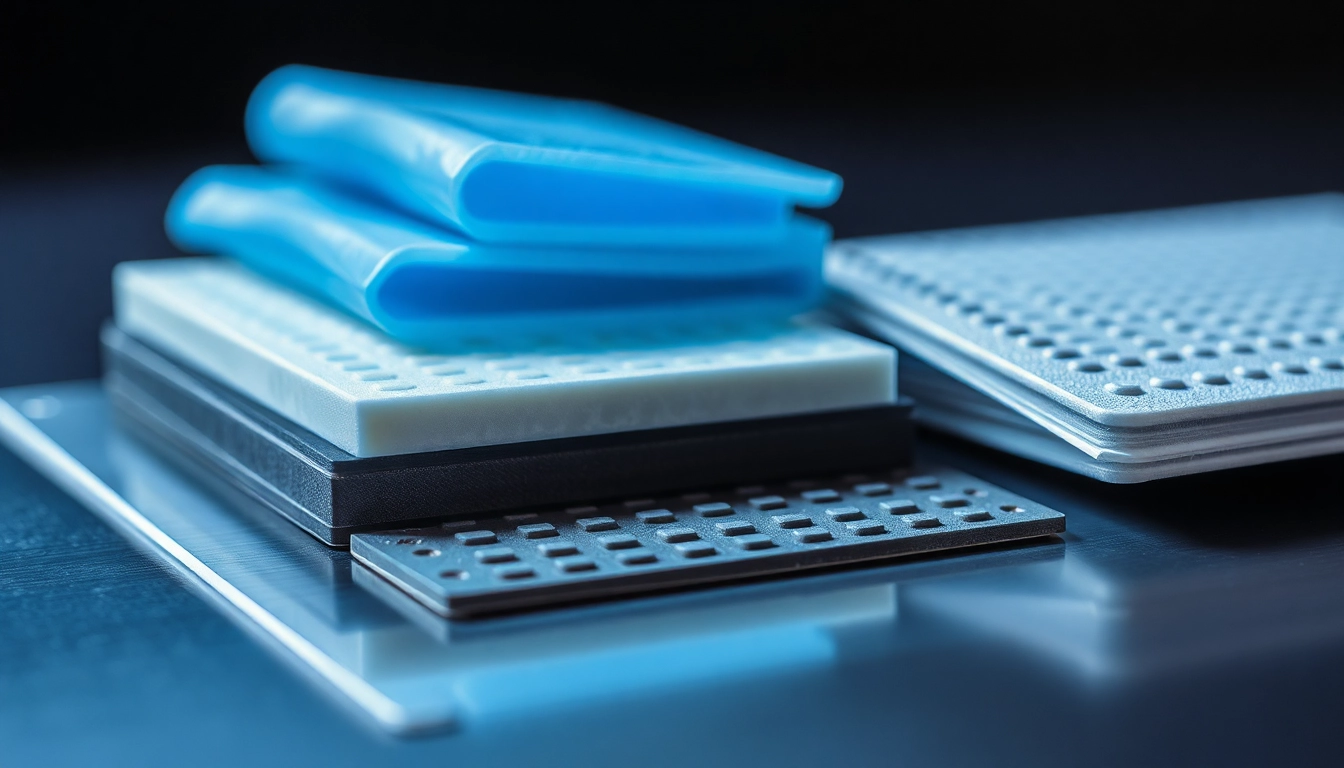

Thermal management materials refer to a range of substances employed in electronic systems to control heat generation and dissipation. These materials act as barriers or conduits for heat flow and play a vital role in protecting sensitive components from overheating. They can be classified into three main categories: thermal interface materials (TIMs), phase change materials (PCMs), and insulating materials. Each type serves a unique function, tailored to the specific requirements of various applications in the electronics industry.

Importance of Thermal Management in Electronic Devices

The technological advancements in electronics have led to smaller, faster, and more powerful devices, but with increased power comes increased heat. Effective thermal management is essential for several reasons:

- Performance Optimization: Excessive heat can degrade performance. Properly implemented thermal management ensures that devices function within their specified temperature range.

- Component Longevity: Heat is one of the primary causes of failure in electronic components. By managing heat effectively, the lifespan of the device can be significantly increased.

- Safety: Overheating can lead to catastrophic failures, including fires. Adequate thermal management helps mitigate these risks, ensuring safe device operation.

Popular Types of Thermal Management Materials

Several types of thermal management materials are utilized in electronics, each with its specific properties and applications:

- Thermal Interface Materials (TIMs): These materials are placed between heat-generating components and their heat sinks to enhance thermal conductivity and reduce thermal resistance.

- Phase Change Materials (PCMs): These substances absorb and release thermal energy during phase transitions (solid to liquid and vice versa), helping to regulate temperature fluctuations in devices.

- Thermal Conductive Adhesives: Used to bond components while providing heat transfer capabilities, these adhesives are essential in applications where mechanical fastening is not suitable.

Key Properties of Thermal Management Materials

Thermal Conductivity Explained

Thermal conductivity is a material’s ability to conduct heat. It is a critical property for any thermal management material, as higher thermal conductivity allows for more efficient heat dissipation. Materials are evaluated based on their thermal conductivity values, which are typically measured in watts per meter-kelvin (W/m·K). For instance, metals like copper and aluminum have high thermal conductivities and are commonly used in heat sinks and other heat dissipation applications.

Durability and Reliability in High-Temperature Applications

Thermal management materials must withstand demanding environmental conditions, particularly in high-temperature applications like aerospace and automotive industries. Materials susceptible to degradation can lead to device failures. Therefore, selecting materials that maintain their properties at extreme temperatures is essential. For instance, silicone-based thermal gels are known for their durability in high-temperature scenarios.

Electrical Insulation and Safety

In addition to thermal properties, many thermal management materials also provide electrical insulation. This dual functionality is particularly crucial in preventing short circuits in electronics. Materials such as insulated gap pads or thermally conductive silicon gels offer excellent insulation while facilitating efficient thermal transfer.

Applications of Thermal Management Materials

Use in Consumer Electronics

Consumer electronics, including smartphones, laptops, and gaming consoles, are primary fields for thermal management materials. As devices become more compact and powerful, effective heat management solutions are required to prevent throttling and ensure longevity. For instance, high-performance gaming laptops utilize thermal pads and TIMs to maintain optimal temperatures during intense gaming sessions.

Role in Automotive and Aerospace Industries

In automotive and aerospace applications, thermal management is vital for safety and performance. Electric vehicles (EVs) rely on thermal management materials to regulate battery temperatures, which can impact performance and safety. In aerospace, materials must not only manage heat but also meet strict weight and reliability demands, making advanced composites and PCMs key materials for these applications.

Thermal Materials in Renewable Energy Solutions

The renewable energy sector, particularly solar and wind energy, benefits significantly from thermal management materials. In solar panels, for example, proper thermal management protects photovoltaic cells from overheating, which can otherwise reduce efficiency. Similarly, effective cooling of wind turbine generators is essential for operational reliability, where thermal interface materials play a crucial role.

Best Practices for Selecting Thermal Management Materials

Assessment of Specific Application Needs

When choosing thermal management materials, it’s crucial first to assess the specific application needs. Different scenarios demand unique properties, such as flexibility, thermal conductivity, and electrical insulation. For instance, aerospace applications prefer lightweight materials with high thermal stability, while automotive applications might prioritize durability and high thermal transfer capability.

Evaluating Performance Metrics

Selecting the right material goes beyond merely understanding its thermal properties; evaluating performance metrics is equally critical. Some key performance indicators include:

- Thermal Resistance: Lower thermal resistance values indicate better performance in transferring heat.

- Operating Temperature Range: Materials must be capable of operating efficiently within the required temperature range of the application.

- Longevity and Reliability: Assessing a material’s expected lifespan in real-world applications can help avoid premature failures.

Common Mistakes to Avoid in Material Selection

Choosing thermal management materials isn’t always straightforward, and several common pitfalls can lead to suboptimal outcomes. Here are a few mistakes to avoid:

- Overlooking Temperature Peaks: Failing to account for temperature spikes can lead to the selection of inadequate materials that cannot withstand extreme conditions.

- Neglecting Long-Term Effects: Short-term testing is not enough; consider the material’s performance over its expected lifecycle.

- Not Considering Compliance: Ensure that selected materials comply with industry standards and regulations, especially in sectors like automotive and aerospace.

Future Trends and Innovations in Thermal Management Materials

Emerging Materials and Technologies

The field of thermal management materials is continually evolving, and emerging technologies promise even more efficient thermal solutions. These include nanomaterials, which show fantastic potential due to their high surface area and unique thermal properties, and bio-inspired materials that mimic natural heat dissipation processes. Such innovations could revolutionize how we approach thermal management in electronics.

Impact of Sustainability on Material Development

Sustainability is becoming an increasingly important factor in material development. Manufacturers are looking for ways to minimize environmental impact, leading to the exploration of biodegradable materials and recyclable options. Additionally, the circular economy principles influence material selection, emphasizing durability and reusability.

Predictions for Market Evolution

The market for thermal management materials is expected to grow significantly, driven by advances in technology and rising energy efficiency demands. As electronic devices become an integral part of daily life and industries push for more sustainable practices, the demand for innovative thermal solutions will rise, leading to accelerated research and development in this vital sector.